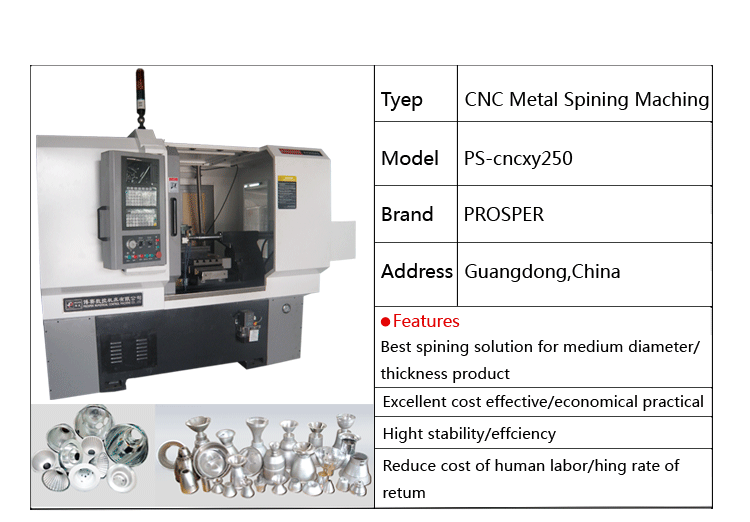

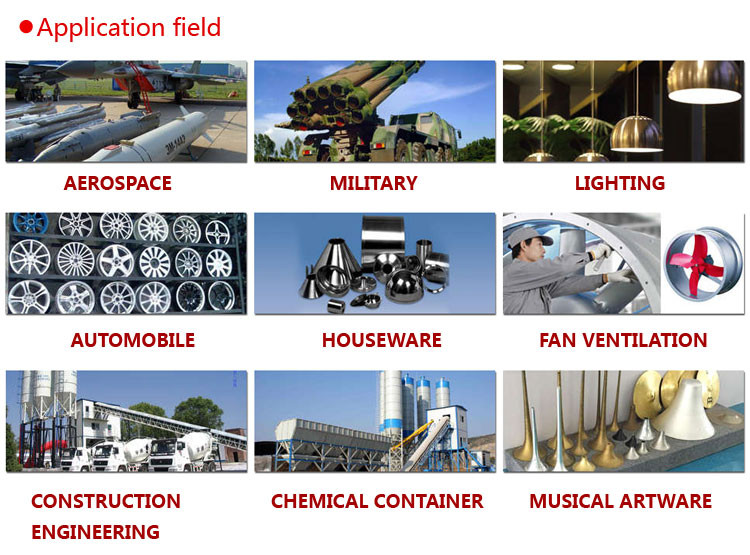

roll forming machine-cnc metal spinning machine PS-CNCXY250 is to meet the need of the spinning products of the industry, especially for the product such as House wares, Light equipment .

This series of machine are characterized by their highly efficient and cost-effective benefits they can provide. The spinning process technology can produce various shapes of products, such as in shapes of cylinder, cone, parabola, trumpet and bullet. It not only produces in large quantity, but also carries out the trial-manufacture testing and completes the trimming and rolling of the edge and contraction and extrusion of the products. The machine is suitable for processing of the aluminum alloy plate, steel plate, stainless steel plate and many other materials.

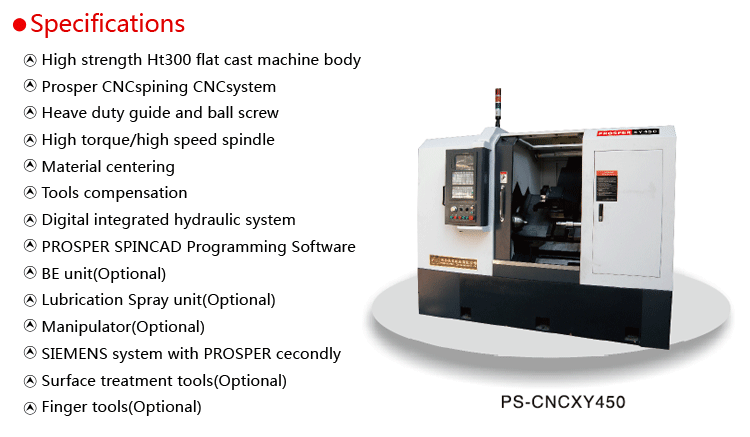

Main Configurations and Functions

lDual-tool holder

l2+2 tools positions(tool turrets)

lSpherical guide

lCircle centering device

lHydraulic pressure station

lRoll support with compensation

lProduct ejector

lManipulator(Optional)

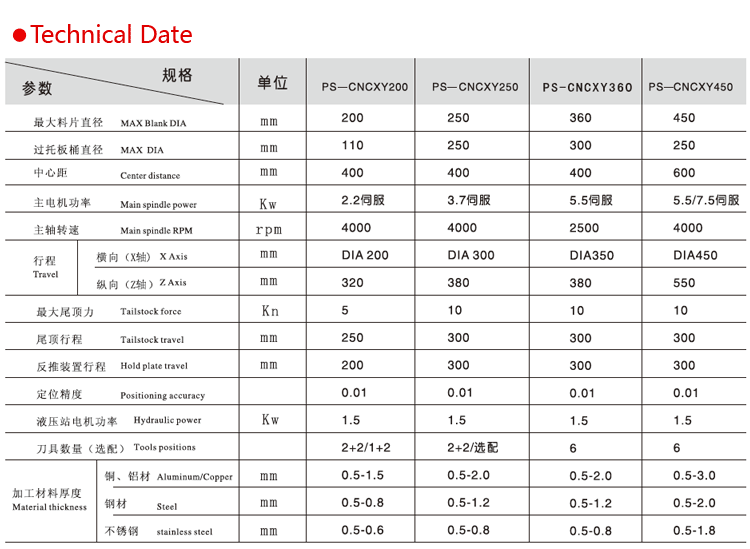

| SpecificationsModel | PS-CNCXY250 |

Max. Blank Circle Diameter | 250mm |

Center Distance | 350mm |

X axis path | 400mm |

Z axis path | 380mm |

Main Spindle Motor | 3.7kw |

Spindle Rotational Speed | 10-4000 rpm |

Max. Tailstock Force | 10 kn |

Tailstock Travel | 300 mm |

Tool Turret (Spinning Roller) | 1+1 |

Sheet Thickness Approx ( Aluminum ) | 0.5~2.0mm |

Sheet Thickness Approx ( Plain Steel ) | 0.5~1.0 mm |

Sheet Thickness Approx (Stainless Steel ) | 0.5~0.6 mm |