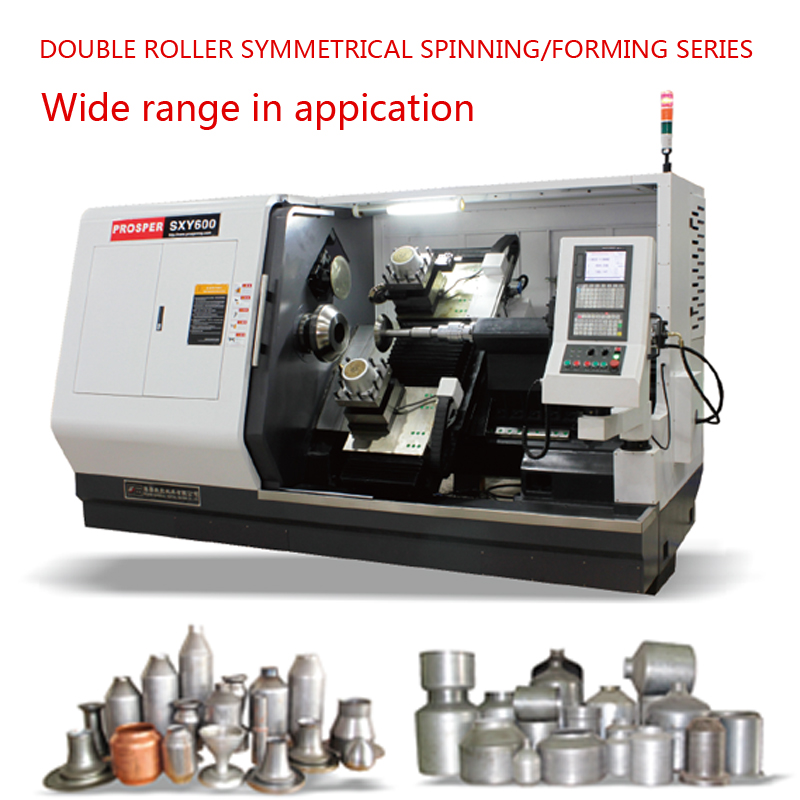

Spinning technology by rotating the workpiece so that the press force from point to point line, from the line to the surface, while in a certain direction with a certain pressure hob give the metal material deformation and flow in this direction and forming an expected shape .PROSPER production of CNC spinning machine represents the highest level of domestic spinning technology.

Features of Spinning technology:

1. Spinning is a continuous partial forming processing, small instantaneous deformation zone, small total deformation force.

2. Some complicated parts of curved shape or hard difficulty deformable material, it is impossible to use the traditional metal forming process, but with CNC spinning method, it will be easy to process, such as pulleys, lamps and other accessories.

3. Spinning tolerances can meet up to about IT8, surface roughness of less than 3.2, the strength and hardness are improved significantly.

4. High utilization of materials, tooling costs is only one-fifth –tenth compared with expensive pressing/stamping die. CNC spinning with economy budget and multi-production batch \ workpiece structure \ equipment and labor costs are related. Spinning is always goes together with ultrasonic washing, stamping, cutting, ultrasonic cleaning, plating processing and other technology auxiliary applications to get the best profit.

5. The best shapes of the spinning are rotational shapes, mainly barrel, conical lines, curved shape and bus combination.

6. The best materials are: iron, aluminum, stainless steel, copper and the like other plastic metals.

Created by PROSPER CNC SPINNING