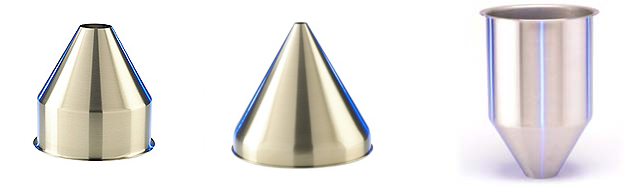

Spinning is the process of moving a spinning roller over a metal blank. The metal spinning process starts with a sheet metal blank that rotates on a lathe. The metal disc is pressed against a tool (called a mandrel or a chuck) with a tailstock. The metal disc, tailstock and tool rotate in a circular motion and a roller manipulated with CNC controls presses against the metal to form the metal over the tool through a series of passes by the roller. The resulting part is a piece that duplicates the exterior portion of the tool it was formed on. PROSPER utilizes CNC technology to develop programs for your part which allows programs to repeat with precision, piece after piece.

Cost and Engineering Benefits of Preformed BlanksPROSPER has over a half century of producing preform blanks with our deep drawing and roll plus welding capabilities. Since metals can only be worked so much before requiring a thermal treating of some kind or failing, spinning alone is sometimes not the optimal processing method. Utilizing a combination of welded blanks with aerospace quality welds or seamlessly deep drawn preforms can reduce processing costs of spun only parts and dramatically improve the level of quality by minimizing the straining or thinning of the material. Minimizing straining of material is especially important in materials that strain harden like stainless steel, nickel, and titanium alloys or materials in general that have low elongation. Applications requiring good fatigue life or need to minimize risk from cracking normally benefit using a gently produced preform then spinning it to the final shape.

This two step process can avoid issues common with metals that are well worked or highly strained.

Another added benefit using preforms can be the elimination of weld joints and the need to manufacture multiple parts. Round parts made in two pieces and welded together can sometimes be manufactured in one piece. Using a deep draw preform and spinning a final shape, the once two piece weldment now is a seamless part. This typically improves quality and the ability of the part to perform while normally reducing lead time, supply chain complexity, and or cost. Call us today and we would be happy to see what options you have to do more.

Manual spinning, also referred to as hand spinning, is another form of spinning that PROSPER offers. Manually spinning is much like CNC spinning except the roller used to form the part is manipulated manually. Since the force a person can produce is much less than the 10,000 to 38,100 pounds of force our CNC equipment can produce, manual spinning focuses around lower strength materials and thinner part geometries.

We offer a high quality metal finishing options on most products manufactured at PROSPER. Most exterior and or interior surfaces may be ground smooth to 125 Ra. or 32 Ra. with a brush finish depending on the part configuration. For larger projects, we have established partners ideal for painting, powder coating, buffing, conversion coatings, anodizing, passivisation and electro-polishing. The combination of our in-house and partner surface finishing processes and robust knowledge base is powerful and available to you to get the surfaces you need whether it be aesthetically pleasing, smooth, mirror like and or corrosion resistant. The right part material, surface preparation and surface treatment is paramount when your application demands it.

We understand and we work hard get what our customers need. Contact us however you prefer and we will work to support your needs. Become our customer, will deliver what you need.High quality metal finishing with a brushed finishes 125 or 32 Ra.

1.High quality metal finishing with a brushed finishes 125 or 32 Ra

2.Interior and exterior metal finishing available.

3.Expert staff available at hand to answer your questions about metal polishing.

4.Additional surface treatments and coatings available through our partners.